OUR SERVICES

Technology

In the history of technologies a lot of processes can be found where the final product should show an endless variety. The first and most well known among them was the Gutenberg typography. The semantically meaningless, poured in moulds, movable letter types are capable to be assembled to any meaningful word, sentence and finally to produce any book in mass-scale and in low price. Similarly to this, the esthetically neutral, poured in moulds gypsum surface elements of non-tectonic systems are capable to be assembled to realize any building structure.

✓ OPEN BUILDING SYSTEM

The non-tectonic systems represent the open systems of building industrialization. It means that the phases of design-manufacture-assembly are coordinated to the given task.

✓ VARIABILITY

It is possible to create a structural and technological variation meeting perfectly the local conditions and requirements The technology can perfectly satisfy the local geographical, weather, seismic needs, the social, cultural and religious traditions.

✓ TECHNOLOGICAL FEATURES

– no hydrostatic pressure during concreting

– no need for after-treatment of the concrete

– the load-bearing capacity of these special reinforced concrete structures much exceeds their own weight

– the gypsum elements have perfect surface, no need for plastering

Specific design methodology

The technology can realize most economically any architectural concept on the level of mass-production and industrialization. We have elaborated a non-sophisticated but special design method for engineers designated by our partners. The task of these architects should be to translate a given architectural concept to the „language” of Gremound non-tectonic systems, that is to adapt a design while knowing the complete series of the manufactured elements.

Construction Technology – Concrete Technology

The essence of this technology, compared to traditional concrete-technologies, is that construction requires significantly lower levels of energy, time and resources used – henceforth it is maximally cost-effective. The prefabricated elements made from an amalgamation of gypsum and fast-curing concrete allow for construction that is 7 times faster than that of construction using the conventional concrete ossature. This technology brings the possibility of a previously unknown diversity of building shapes.

This is explained by the reason that instead of producing ossatures the production process is aimed at creating the casting mould of monolithic reinforced concrete. Simplicity, in our vision encompasses the usage of local resources and training as well as employing local workforces. Subsequently, this allows for the creation of efficiency, optimization of workflow and a ‘quick to master’ technology. Within the construction industry, Gremound System is internationally the first to cater to mass production through the utilization of Ferro-concrete structures. We firmly believe that we have created the construction technology that is able to provide the solution to the ever-growing, demanding problems of the low-cost housing market.

This technology brings the possibility of a previously unknown diversity of building shapes. This is explained by the reason that instead of producing ossatures the production process is aimed at creating the casting mould of monolithic reinforced concrete:

- Through its flexibility (any optional size of inner space, the visibility or lack of visibility of the modules’ „ribbing”, the diversity of their thickness etc.) Gremound can be the most suitable and economically efficient solution in any building process.

- Besides gypsum as the main bonding material, the unimaginably wide range of modules may contain several other additional substances, too.

- The additional substances offer the architects enough ground to set the physical characteristics of the building (heat lagging, heat storage, managing water vapour, fire-protection, resistance against different weather conditions etc), according to the particular climatic conditions of the location.

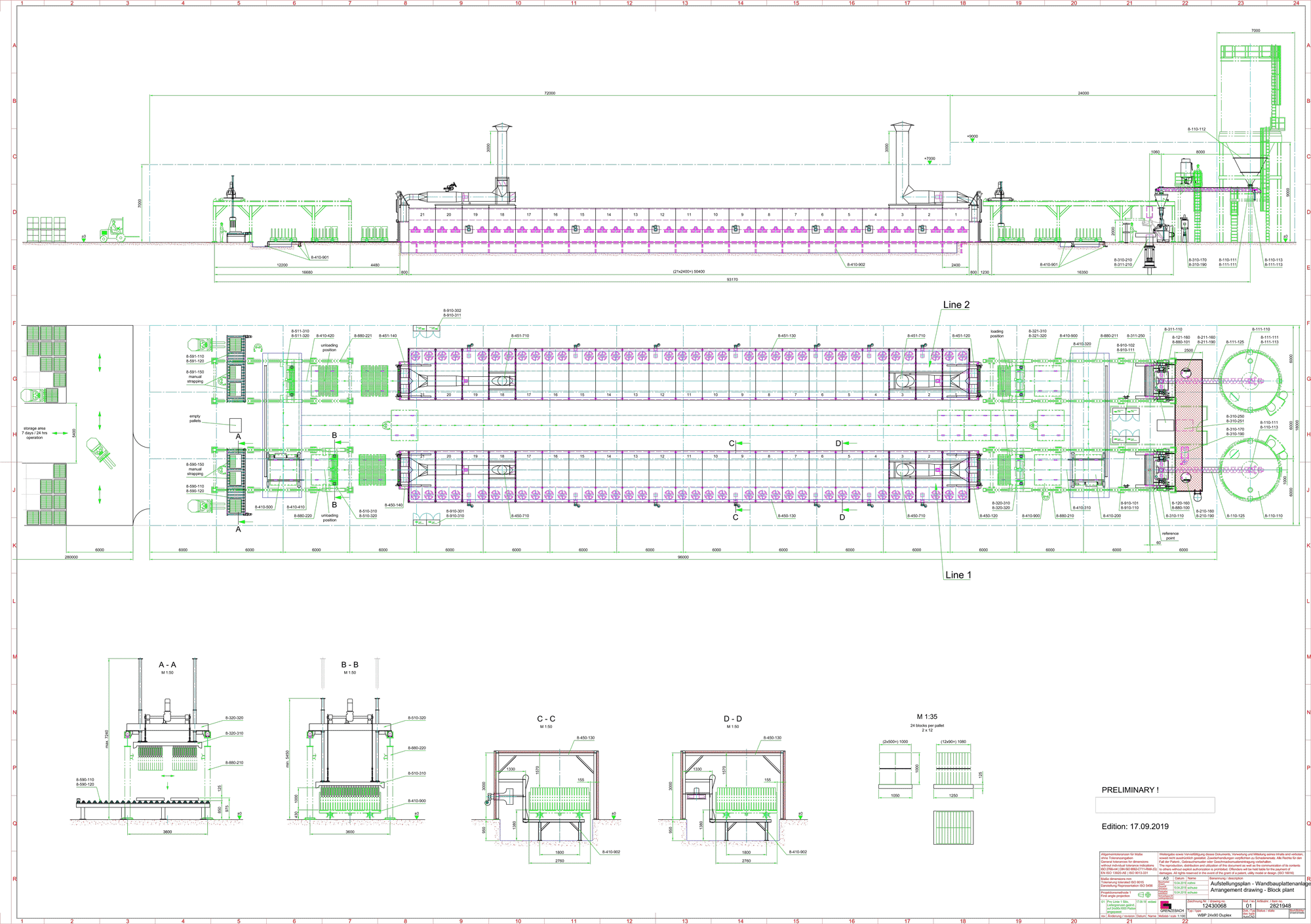

- Diversity means that it is up to the designer’s decision either to set up a fast, intensively automated production unit or to install a slower, less machinery-using facility, at the same time employing a greater number of unskilled labourers.

Investment

Our mission and values

Summing up, the value of Gremound system is not in the perfectness of its appearance but in its ability to quickly adapt and to make needs and offer meet. That ability is based on diversity.

Every business has an impact on society and the way that people live their lives, from the products and services they deliver.

The issue of building mass social housing is one of the most difficult to answer around the world. Exceptional people are needed to solve the most difficult problems. We believe that exceptional.

Annual Duplex line production

living square meters

Annually raw materials used

tons of gypsum

CUBIC METER CONVENTIONAL CONCRETE

CUBBET METER GREMOUND CONCRETE

TONS OF CONCRETE

Contact us

If you are interested in government Low Cost Housing and Social Housing programs